DC SUPER FLEX

DC SUPER FLEX is Dancutter’s extremely flexible cutter.

Size range: 75 – 150 mm, 3” – 6”

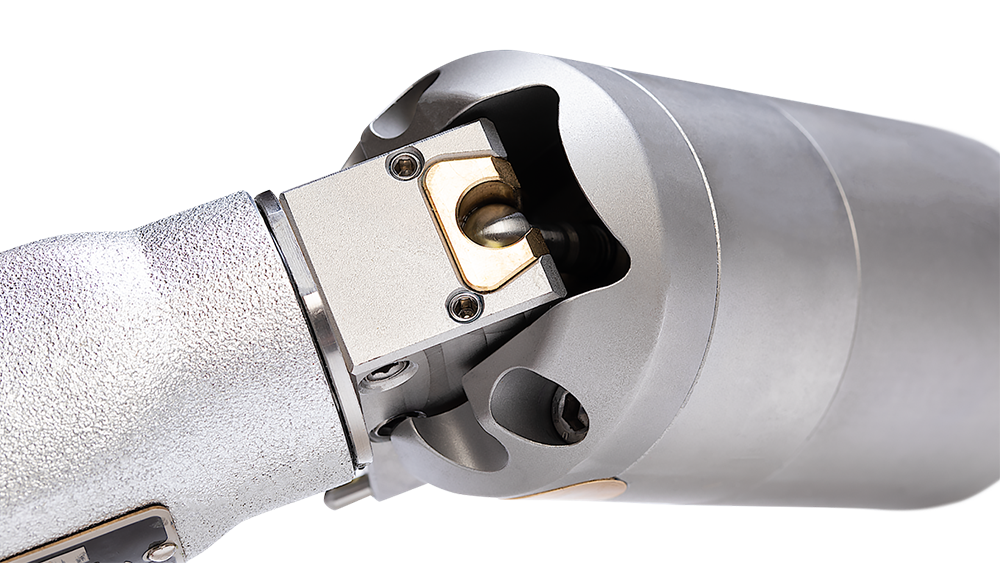

This dynamic cutter can effortlessly move through several 90-degree bends in 100 mm pipes. Whether dealing with straight runs or intricate bends, the DC SUPER FLEX operates with unmatched precision. Control Unit is included.

Enquire about this product

1/

DC SUPER FLEX

Key features

Powerful and Flexible

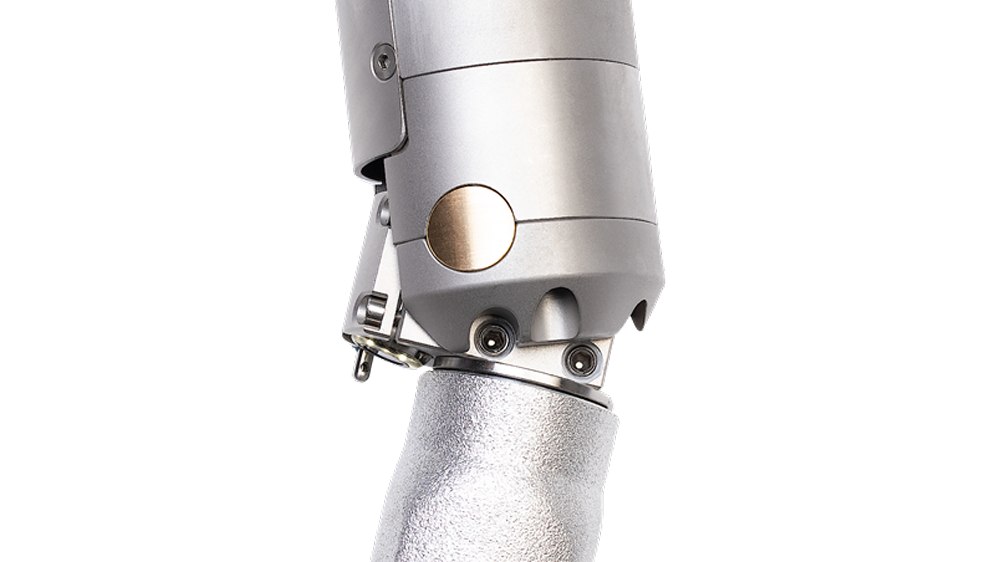

Extremely flexible in 45° and 90° bends. Effectively cuts, grinds, and mills in diverse materials.

Advanced Control Unit

Experience smooth and effortless control of your cutter with Dancutter's DC SUPER FLEX and DC MAXI FLEX control unit. Equipped with two joysticks, the control unit provides precise control over the motor rotation and cutter arm movements, allowing you to raise, lower, expand, and contract the cutter with ease.

High Manoeuvrability

Automatic feeder and built-in slip ring for seamless back-and-forth movement.

360-degree Continuous Rotation

Enjoy unrestricted operation with a continuous 360-degree continuous rotation feature.

Customizable Supply Hose

Choose between a 25-meter or 50-meter hose for tailored operational flexibility.

Enhanced Functionality

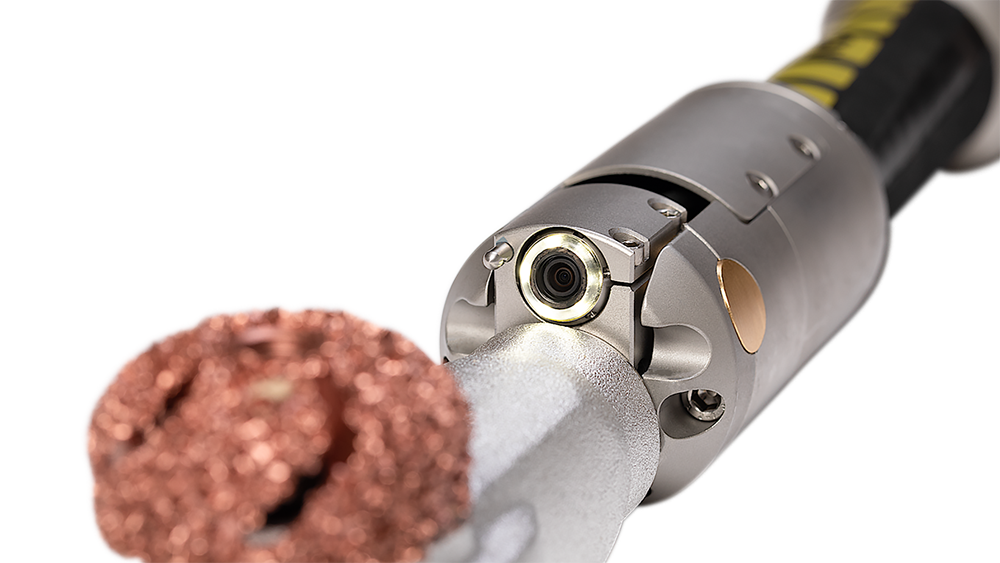

The cutter is equipped with a spray nozzle for camera cleaning with air or fluid.

Specification

Download spec sheet-

Pipe diameter

Dia. 75 - 150 mm, 3" - 6"

-

Bends

45° and 90°

-

Supply Hose Options

25 or 50 metres, 82 or 164 ft

-

Expansion / Contraction

60 mm - 2,4"

-

Rotation

360° Continuous Rotation

-

Grind, Mills and Cuts

PVC, Liner, Concrete, Iron, Cast Iron, Stainless Steel

Need help finding the right cutter?

We are ready to answer your questions.

Videos

A video presentation of the DC SUPER FLEX

How to Mount Different Cutting Heads

Product information

Download spec sheet

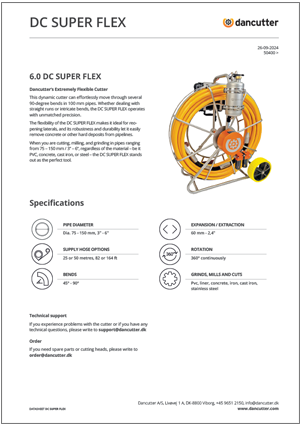

Dancutter’s Extremely Flexible Cutter

The flexibility of the DC SUPER FLEX makes it ideal for reopening laterals, and its robustness and durability let it easily remove concrete or other hard deposits from pipelines.

When you are cutting, milling, and grinding in pipes ranging from 75 – 150 mm / 3” – 6”, regardless of the material – be it PVC, concrete, cast iron, or steel – the DC SUPER FLEX stands out as the perfect tool.

More information

The DC SUPER FLEX is designed for single-person operation. Its setup is swift and straightforward, allowing for quick transitions between tasks. The wheeled stainless-steel frame holds the supply hose, control unit, and cutter, ensuring everything is at arm’s reach. Always ground the equipment for safety, especially when using the grinder in dry pipes, to prevent static electricity hazards.

Experience unparalleled efficiency and control with the DC SUPER FLEX – your number one choice in advanced pipe cutting solutions.

Experience smooth and effortless control of your cutter with Dancutter’s DC SUPER FLEX and DC MAXI FLEX control unit. Equipped with two joysticks, the control unit provides precise control over the motor rotation and cutter arm movements, allowing you to easily raise, lower, expand, and contract the cutter.

Featuring a foil keyboard with tactile buttons and LED indicators, the control unit gives you clear feedback when you adjust the rotation speed, turn on the milling cutter, or activate the spray nozzle to clean the camera with air or sprinkler liquid. The keyboard’s foil surface is specifically designed for tough industrial conditions and outdoor use, ensuring reliable performance in any environment.

Built into a sturdy case, the control unit includes a 12″ color screen in the lid that displays a sharp and accurate image of the cutter’s position inside the pipe. With a brightness of 1000 nits and an anti-reflective coating on the optically bonded glass, the screen provides excellent visibility even in bright conditions. You can easily switch between images from the cutter’s camera and an external camera, and the controls can be mirrored to suit your movements for maximum comfort and ease of use.

In addition to its precise control capabilities, the control unit also includes a range of advanced features to enhance your work. You can record and save videos directly to a USB stick, or connect external cameras, monitors, or FPV headsets using the input and output connectors. Whether you mount the unit to the cutter’s frame or use an extension cable (up to 15 meters) to work from a distance, the control unit offers unmatched performance and versatility for your cutting needs.

- Smooth back and forth movement – An automatic feeder and slip ring are built into the frame, so the supply hose can be smoothly moved back and forth during the work.

- 360-degree continuous rotation – The cutter is equipped with a built-in slip ring which enables it to work freely in a continuous 360-degree rotation.

- Spray nozzle for cleaning the camera – the spray nozzle is also operated from the control unit.

The DC SUPER FLEX is designed for minimal maintenance, built with high-quality stainless steel. It features an oil lubricator and water separator, ensuring optimal performance. To enhance efficiency, we recommend using a refrigerated dryer on the compressor, reducing the water content in the air to below 20 g/m3. This practice ensures the cutter operates in a clean, dry environment, maximizing efficiency and extending its service life.