Service and Repair

We are here to help!

If you have a question or problem and need support – call us at +45 9651 2150, write to support@dancutter.dk or fill out the service form below. We will get back to you within one workday.

What people are saying

1/

Elevating Service to Outstanding Levels

At Dancutter, we understand that exceptional service is not just a commitment, but a necessity. Our dedicated Service Team, in partnership with our global network of dealers and service centres, guarantees a superior level of service and the efficient upkeep of your Dancutter systems. Our global service organisation is designed to address the specific needs of our customers worldwide, offering professional technical services and rapid support for urgent requirements.

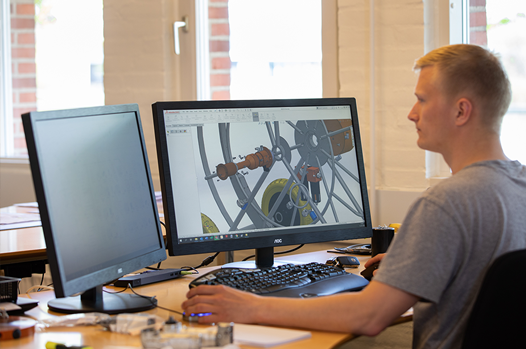

Choose Dancutter for Uninterrupted Technical Support and Maintenance

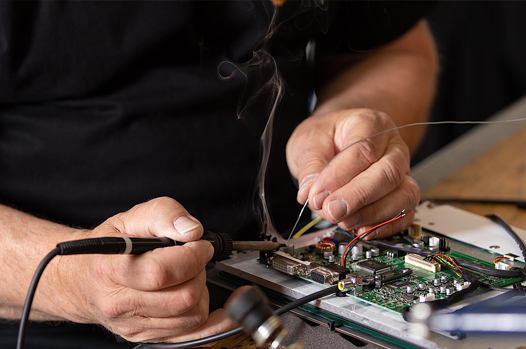

With Dancutter as your service partner, you can expect continuous technical support, meticulous maintenance, comprehensive repair services, top-quality spare parts, and custom-designed toolboxes. Our complete service solutions are tailored to let you focus on your core business, with the confidence that your equipment is in expert hands.

Accessories and Spare Parts by Dancutter

Our dynamic After-sales team is dedicated to nurturing customer relationships. Working closely with our dealers, we ensure that every customer enjoys premium service. Our offerings also include a wide array of accessories and spare parts for your Dancutter products. Discover how Dancutter Service can rejuvenate your equipment and provide straightforward and adaptable solutions to your immediate challenges.

For non-EU customers sending equipment to the EU for repair or maintenance and planning to export it back, please complete our shipping form to avoid customs duties and VAT.